Essential Functions to Look for When Choosing a Membrane Switch

Essential Functions to Look for When Choosing a Membrane Switch

Blog Article

Recognizing the Performance of Membrane Layer Changes for Interface Instruments

The capability of membrane changes represents a considerable development in interface style, incorporating effectiveness with aesthetic versatility. These switches operate with a multi-layered structure that equates individual interactions into electrical signals, permitting for both small formats and resilience versus environmental aspects. As markets progressively prioritize customer experience, comprehending the nuances of membrane button modern technology ends up being vital. What ramifications do these improvements hold for future applications, and just how might they redefine customer communications throughout numerous tools?

What Are Membrane Layer Buttons?

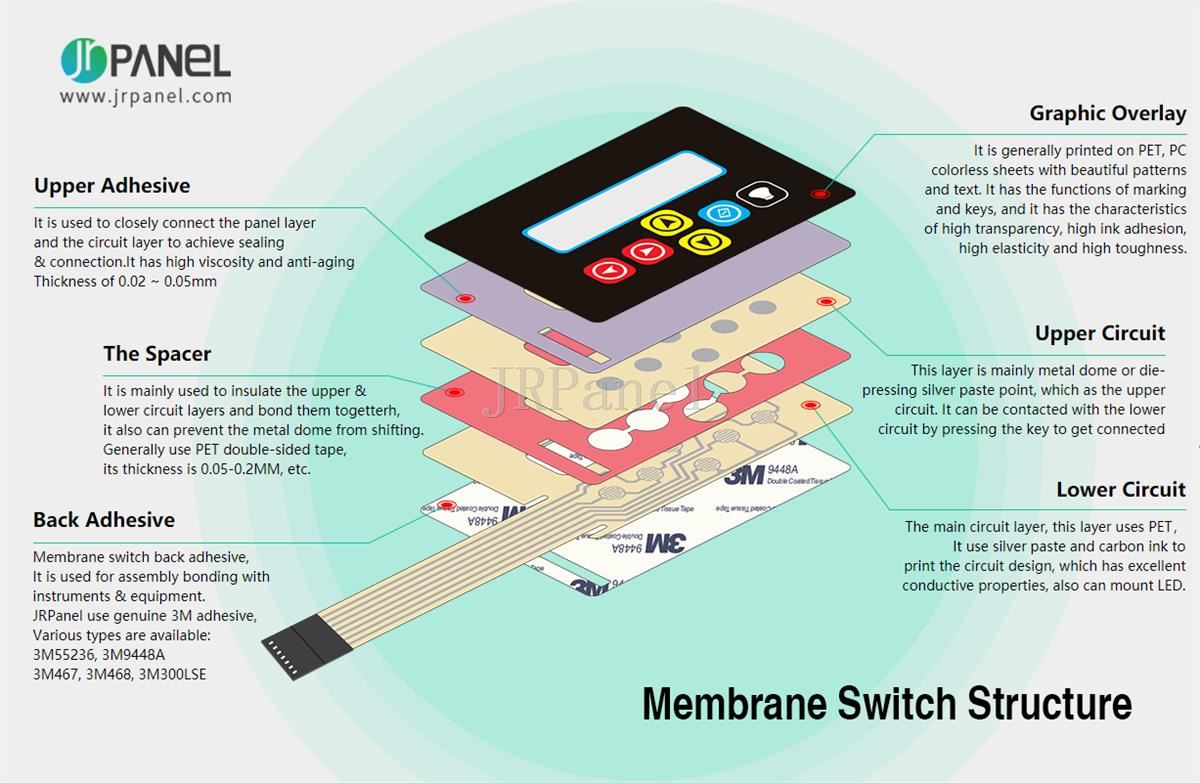

Membrane buttons are cutting-edge interface devices that help with user interaction with electronic tools. These functional parts include numerous layers, consisting of a visuals overlay, spacer, and a published circuit layer. The layout permits for a smooth integration into numerous electronic devices, enhancing both the visual and functional facets of interface.

Membrane layer switches are frequently employed in a vast array of applications, from home devices to commercial machinery and medical tools. Their building and construction commonly includes a thin profile, making them an excellent option for compact layouts. The tactile feedback provided by these buttons can be crafted to meet details individual choices, making certain effective communication between the user and the tool.

Longevity is one more substantial advantage of membrane layer buttons, as they are resistant to dust, dampness, and chemicals, which improves their life-span popular settings. Additionally, these switches can be personalized in regards to form, size, and visuals style, permitting branding and user-specific attributes. Generally, membrane layer switches represent a functional option for enhancing customer experience in electronic tools, integrating functionality with aesthetic charm in an efficient way.

Just How Membrane Switches Over Work

Operating on an uncomplicated principle, membrane layer changes utilize a split construction to sign up user input properly. Each button consists of several layers, consisting of a printed circuit layer, a spacer layer, and a leading visuals layer, which are developed to work together flawlessly. When a user presses the leading layer, it presses the spacer layer, bringing the conductive aspects of the circuit layer into contact with each various other.

This call creates a closed circuit, signaling the device to implement a details feature. The layout enables various arrangements, consisting of tactile comments, which can improve the individual experience by offering a physical sensation upon activation. The materials utilized in membrane layer buttons often include adaptable substratums, such as polyester or polycarbonate, which make sure durability and strength against deterioration.

Key Advantages of Membrane Layer Buttons

An additional considerable benefit is their compactness. Membrane buttons are thin and light-weight, which allows manufacturers to conserve space in their tools without giving up capability. This function is specifically advantageous in applications where weight and quantity are important considerations.

In addition, membrane buttons are resistant to dirt, wetness, and chemicals, improving their sturdiness. This resilience extends their life expectancy and reduces the requirement for regular substitutes, leading to cost click resources savings over time.

Moreover, the responsive feedback provided by membrane layer switches can be enhanced to boost customer interaction. They can include attributes such as raised buttons or distinct clicks, improving functionality and user experience.

Applications Throughout Industries

Interface devices using membrane layer buttons are widespread in a vast array of industries, showcasing their adaptability and performance. Membrane Switch. In the medical market, you can try here membrane layer buttons are indispensable to devices such as analysis tools and patient tracking systems, where their durability and simplicity of cleaning are vital for preserving hygiene standards. In a similar way, in the automobile market, these switches are utilized in dashboard controls and infomercial systems, supplying a sleek and modern-day user interface for individuals.

Additionally, the customer electronic devices sector benefits from membrane layer switches in devices and portable tools, where compact design and user-friendly interfaces boost customer experience. Industrial applications likewise take advantage of membrane layer changes for control panels in equipment and automation systems, emphasizing their toughness and resistance to harsh settings.

In the aerospace and protection markets, membrane buttons are made use of in cockpit controls and equipment, where reliability and efficiency under severe conditions are paramount. In addition, the gaming market progressively incorporates membrane layer switches in controllers and gallery devices, contributing to an engaging customer experience. Overall, the convenience of membrane switches allows their widespread usage across numerous industries, highlighting their significance in contemporary interface style.

Future Trends in Membrane Layer Switch Modern Technology

Additionally, the use of sophisticated products, such as polycarbonate and polyester movies, is expected to increase, offering improved sturdiness and resistance to environmental stress factors. These materials add to the general long life of membrane buttons, making them appropriate for harsher industrial applications.

Additionally, the consolidation of clever technology, including IoT connection, will enable membrane layer switches to interact with various other tools and systems, promoting a more interactive individual experience. This trend lines up with the expanding demand for clever gadgets throughout various markets, from healthcare to consumer electronic devices.

Lastly, personalization alternatives are anticipated to broaden, enabling suppliers to create bespoke options customized to particular individual demands and choices. These developments will position membrane buttons as vital components in the advancement of customer wikipedia reference interface modern technology.

Final Thought

Finally, membrane switches over stand for an essential improvement in user interface technology, supplying a reliable and functional option for diverse electronic applications. Their split building helps with compact layout, while functions such as tactile responses boost user interaction. The durability against environmental variables additionally solidifies their energy throughout numerous sectors. As innovations in product scientific research and touch noticing technologies proceed, the functionality and applicability of membrane layer buttons are anticipated to increase, enhancing their significance in modern-day electronic gadgets.

Report this page